Domino Dx260i Industrial CO₂ Laser Printer

Domino Dx260i: Adaptable, Robust and Energy-Efficient 20-Watt Laser Coder

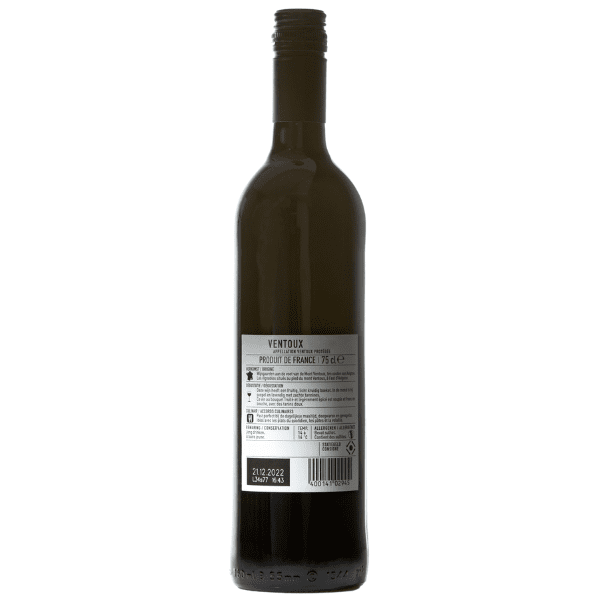

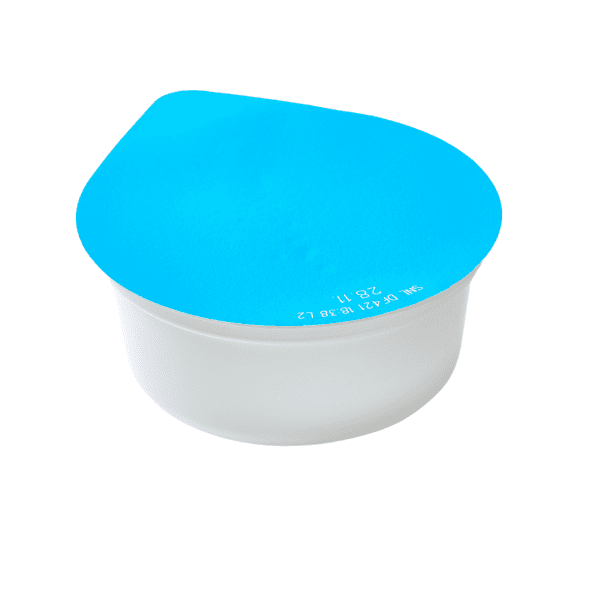

The Domino Dx260i incorporates the same cutting-edge platform used across the Dx-Series, sharing elements of the Dx360i and Dx660i while operating at a lower power rating. It is the perfect answer for producing high-definition, permanent marks on organic substrates such as plastic (PET, PP), paper and corrugated board.

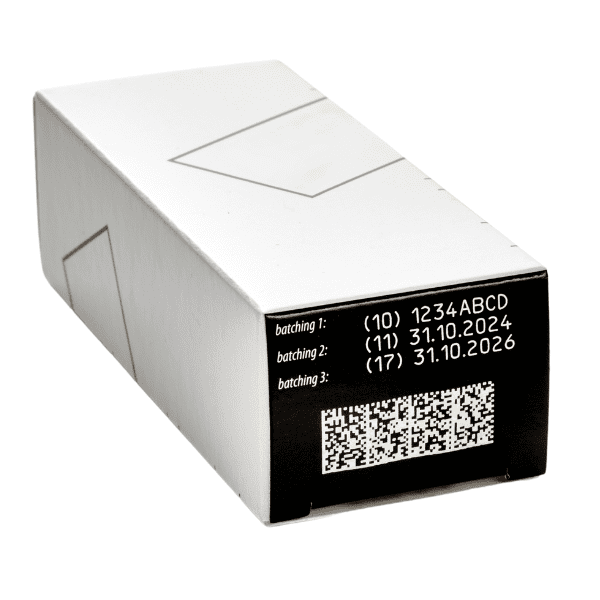

The Domino Dx260i offers all-round marking versatility—text, machine-readable codes, graphics and logos—plus features like real-time clocks, counters and serialisation data to satisfy varied coding needs.

Driven by a 20-watt laser source, the Domino Dx260i excels where smaller code content, modest line speeds or easy-to-etch materials are involved.

Its accuracy and adaptability guarantee clear, durable, tamper-proof identification, supporting traceability throughout the supply chain.

Why Pick the Domino Dx260i Industrial CO₂ Laser Printer?

![]()

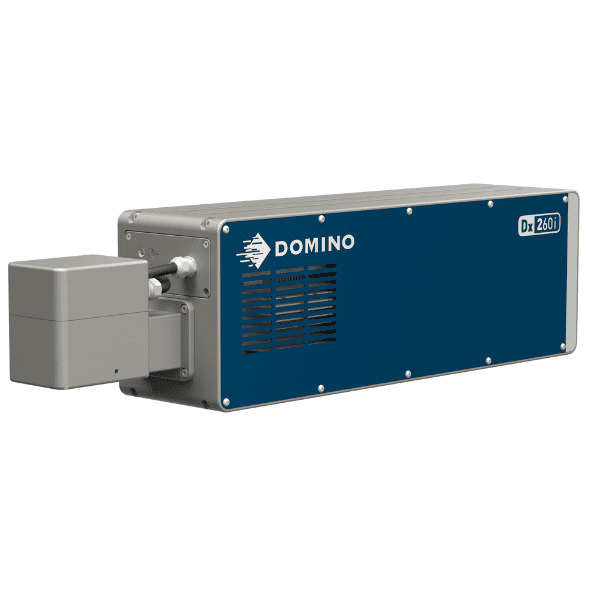

With more than 50 predefined beam-delivery configurations, a scan head that spins 360 ° and tailor-made options for special projects, the Domino Dx260i laser printer links effortlessly to ERP, WMS and MES frameworks. Its advanced coding algorithm can boost throughput by up to 30 % while keeping code clarity pristine.

![]()

An optional IP65-rated marking head paired with an IP55 controller lets the Domino Dx260i laser printer run faultlessly in wash-down, sticky or dusty zones, trimming downtime and lifting overall efficiency.

![]()

Because details matter, Domino added integration-friendly touches such as a 90 ° angled connector between head and controller. A built-in LED status light on the printhead gives instant confirmation of the Domino Dx260i laser printer status at a glance.

Technical Information

Laser Type

| Dx260i | Dx360i | Dx660i | |

|---|---|---|---|

| Laser technology | CO₂ | CO₂ | CO₂ |

| Laser source | 20W, wavelengths 9.3, 10.2, 10.6μm | 30W, wavelengths 9.3, 10.2, 10.6μm | 60W, wavelengths 9.3, 10.2, 10.6μm |

| Expected lifetime | 50.000h MTBF | 50.000h MTBF | 50.000h MTBF |

Coding Format

| Coding content | Laser optimised fonts for high-speed marking and standard industrial fonts. Graphics, logos, standard industrial machine readable code (1D, 2D) formats (DataMatrix, GS1, QR). Intuitive GS1 Digital Link support. Supporting traceability with serialisation data, sequential and batch numbering. Synchronized clock / Network Time Protocol support (NTP). |

| Focal length | from 80mm to 600mm |

| Marking field | from min. 57x57mm2 to max. 379x582mm2 |

| Advanced Features | Aiming beam, Aim & Code |

| User Interface | Interfaccia utente web-based, possibilità di configurare più punti di accesso paralleli, pannello touch opzionale da 10,1’’ |

System Specification

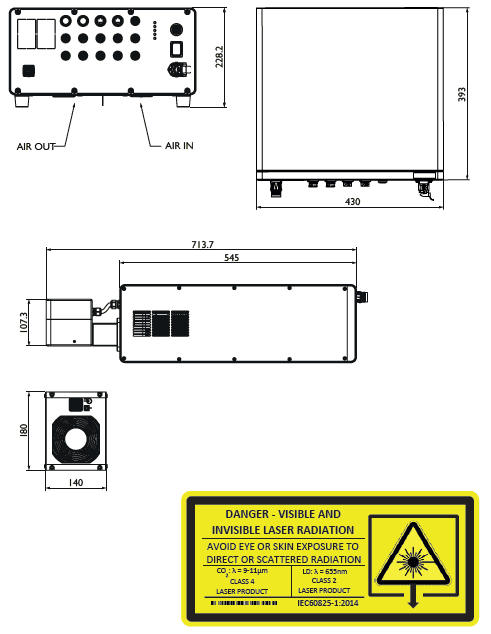

| Scan head orientations | Multitude of scan head orientations including 360° rotatable variant. More than 50 beam orientation variants. Additionally support for customisation and solution integration. |

| Ingress Protection | Laser module: IP54 fan cooled, optional IP65 compressed air cooling. Controller: IP55 |

| Operating temperature | 5˚C – 45˚C |

| Operating humidity | max. 90% RH, non-condensing |

| Electrical supply | multivoltage 90-264V, 50/60Hz |

Input and Outputs, Interfaces

| Inputs/outputs | Multiple inputs and outputs available e.g. extractor, compressed air-kit, encoder, product detect (NPN, PNP), beacon and interlocks, standard GPIO, additional optional GPIO available. |

| Interfaces/Protocols | Ethernet, USB, Dynamark Protocol, EtherNet/IP™ |

Options

| Accessories | Extraction including optimised shrouds, airknife for lens cleaning, multiple brackets, cables and stands for integration support |

| Certification | Marking: CE**, cTÜVus, UKCA / Fulfills requirement: NRTL, ROHS, FDA listed, EMC, FCC. |

** Partly Completed Machinery as per Machinery Directive (2006/42/EC), CE marking according to ROHS (2011/65/EU) and EMC(2014/30/EU)