Domino Ax350i Continuous Inkjet Printer

Domino Ax350i: Always Accurate and Clear Marking

The Domino Ax350i continuous inkjet system ensures flawless marking, even in tough production environments. It lowers mistakes and expenses and operates with zero maintenance required.

Cartridges are replaced in just 20 seconds, keeping your line running with no interruptions. Thanks to an IP66 protection electronics housing and an IP55 grade enclosure, the Domino Ax350i maintains reliable performance even in tough conditions with elevated moisture and direct contact with water or other fluids.

Functions such as the real-time ink level display, single-button Start/Stop control, self-identifying cartridges, and an intuitive 7” touch panel for code management make the Domino Ax350i exceptionally simple to use and easy to fit into any production setup.

The Domino Ax350i produces detailed, premium codes even at very high throughput speeds, ensuring outstanding print quality and comprehensive, tamper-proof traceability of all items.

Why Choose the Domino Ax350i Continuous Inkjet Industrial Printer?

![]()

Effortless to operate and, most importantly, requires no ongoing service. Cartridges are swapped without any need to stop production. The Domino Ax350i is seamlessly integrated with existing machinery and supports popular communications protocols used in automation.

![]()

Outstanding robustness even where operating conditions are most demanding, including the food and beverage sectors.

Even on ultra-fast production lines, the Ax350i always guarantees sharp, error-free marking.

![]()

What’s more, Domino inks maintain exceptional results after demanding post-marking processes such as sterilization and rapid cooling.

This printer connects to your company network and can interface with centralized management software (ERP), guaranteeing correct coding and full traceability through your logistics chain.

Technical Information

The Domino Ax350i fulfills global standards and is distributed in more than 100 countries, holding certifications such as CE, NRTL, CB, and FCC 47CFR Part. 15B.

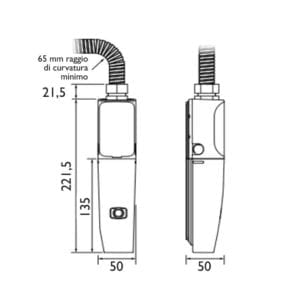

Printhead

| Type | i-Pulse |

| Nozzle Sealing Technology | ✓ |

| Nozzle Sizes | 60 µm – 75 µm – 40 µm – 50 µm |

| Maximum Resolution (DPI) | 82 – 64 – 110 – 98 |

| Formats | Straight, H90 e V90 – Straight, H90 e V90, Straight, Straight |

| Conduit Length | 4 m Standard – 6 m optional |

| Minimum Conduit Bend Radius | 65 mm |

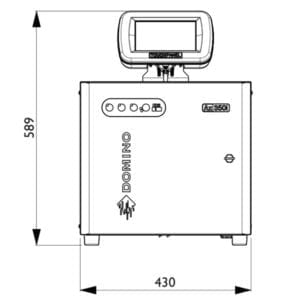

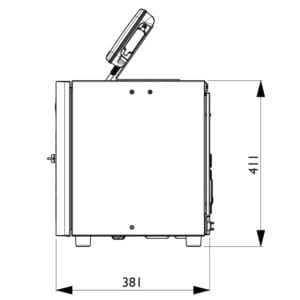

Cabinet

| Material | 304 Stainless Steel Cabinet (5 Sides), Nylon (Door) |

| Dimensions (WxHxD) | 430 x 411 x 381 (mm) |

| Dry Weight | 22 kg |

| Power Supply | 100-240 v : 4 A 50-60 Hz |

| Power Consumption | 40 Watt (Idle); 80 Watt (Printing) |

| Product Detection Input (x1) | ✓ |

| Encoder Input (x1) | ✓ |

| RFID | 13,56 MHz 1,3 uW ERP |

Inks

| Ink Cartridge Capacity | 825 ml – 55 mm (Heavy Duty Ink System) |

| Make-Up Cartridge Capacity | 1.200 ml |

Connectivity

| Domino Protocols | Codenet, Intercomm 0 |

| PC Software Package | QuickDesign V5 & V6 Compatible |

| Webserver | ✓ |

| Domino Cloud Compatible* | ✓ |

* Requires Optional Communication Package

Operation

| User Interface | 7’’ Color Touchscreen (Optional) – 10.4” Color Touchscreen (Optional) |

| Software | QuickStep 3 |

| Operator-Friendly | ✓ |

| One-Touch Start/Stop | ✓ |

Consumables

| Automatic Cartridge Recognition | ✓ |

| Intelligent Level Monitoring | ✓ |

| Make-Up Cartridge Lifespa** | 267 Hours |

| Cartridge Replacement | Operator Task – Requires 20 Seconds – No Line Stoppage |

Maintenance

| Maintenance Type | Maintenance-Free – ITM System |

| ITM Replacement Frequency° | 12 Months |

| ITM Replacement | Operator Task – Requires Less Than 10 Minutes of Line Stoppage |

Environment

| Operating Temperature° | 5-45°C |

| Humidity | 0-90% RH |

| Cabinet Protection Rating | IP66 Electronics Compartment (IP55 Cabinet) |

| Options for Harsh Environments | IP65 Printhead Cover (for Washdown), Positive Air on Printhead (for Dusty Environments), Dryer (for Humid Environments) |

*Speed, Height, and Number of Lines Declared Using the Raster Extension Package.

**Make-Up Cartridge Replacement Frequency with MEK-Based Ink at 21°C.

^ The drop size may vary depending on the surface

°Depending on Ink Type.

Speed (m/s)*

| 1 Line – 5-Drop Characters | (Fastest) Std DPI 7,2 – Max DPI 5,2 |

| 2 Lines – 7-Drop Characters: | Std DPI 2,0 – Max DPI 1,5 |

| 2 Lines – 9-Drop Characters (High Quality) | Std DPI 1,3 – Max DPI 1,0 |

| 1 Line – 24-Drop Characters (Ideal for 2D Code) | Std DPI 0,7 – Max DPI 0,5 |

Dimensions

| Maximum Number of Lines | 5 |

| Print Height* | (in Drops): Up to 32 Drops |

| Print Height* | (in mm): Up to 20 mm |

| Deposited Drop Size^ | 0,31 mm (60 μm) 0,40 mm (75 μm) |

Code Format

| Text | Full Unicode Support |

| Graphics | .bmp Import, Integrated Logo Editor |

| 1D Barcode | EAN 8, EAN 13, UPC A, UPC E, Code 39, Code 93, Code 128, Code 2 di 5, ITF-14, GS1-128 |

| 2D Barcode | Datamatrix, QR Code, Dot Code, Han Xin, Postnet |

*Speed and height declared using the Raster Extension Package.

Hardware Packages

Printer Status Package Option

4-Color Tower Light Output (x1)

4 Printer Status Clean Contact Outputs (x1)

Communication Package Option

USB Port on Cabinet (x1)

Ethernet RJ45 Port (x1)

Extended Communication Package Option

USB Port on Cabinet (x1)

Remote Control Port (x1)

Ethernet RJ45 / Touchpanel 2 Port (x1)

RS232 Package Option

RS232 Port (x1)

GPIO Package Option

4 Inputs / 4 Outputs (x1)

Extended I/O Package Option

2 Inputs / 4 Outputs (x1)

Extended I/O Package Option

High-Speed Raster (ST&HS Type) – Segmented High-Speed DDI Message Format – Script Creation

Professional Printing Package Option

Label templates – Barcode scanning to enter text into the message – Access control

Operator Assistance Package Option

Label Templates – Barcode Scanning for Text Input in Message – Access Management

Peltier Package Option

20% Reduction in Make-Up Consumption – Programmable Auto Shutdown of Printhead and Ink System to Reduce Consumption